What Are Air Brakes?

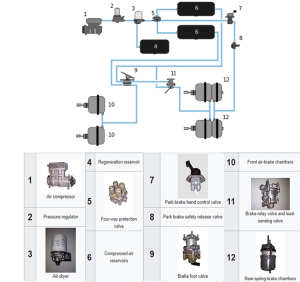

Air brakes utilize compressed air to press on a piston and apply pressure to the brake pad or brake shoe needed to stop or slow the vehicle. This contrasts with hydraulic brakes, which make use of hydraulic fluid rather than compressed air. Also known as pneumatic brakes, air brakes can either be drum brakes, disc brakes, or a combination of both. A compressor mounted on the engine is responsible for pressurizing the air and pumping it into storage tanks, where it is stored until it is needed. Most heavy vehicles have a gauge within the driver’s view that indicates the air pressure stored. There are multiple air circuits in the system.

Source: https://en.wikipedia.org/wiki/Air_brake_(road_vehicle)

When the brake pedal is depressed, air pressure is used to apply the service brakes. The parking brake is engaged by spring force in the parking brake portion of the spring brake chamber when the air pressure in the chamber is released. To release the parking brake, the spring brake chamber fills with air and cages the parking springs. As a result, the parking brake can be used as an emergency brake when air pressure isn’t maintained, or other issues arise.

Uses of Air Brakes

Air brake systems are typically used on extremely heavy vehicles, and some of the benefits they provide only apply to large vehicles. Air brakes are typically used on commercial vehicles and medium- to heavy-duty trucks. Buses, trailers, and also trains also utilize air brake systems. Essentially most vehicles carrying a large payload will make use of an air brake system.

Advantages of Air Brakes

Air brakes are particularly useful in these heavy vehicle applications for a number of reasons:

- Since air brakes run on air, minor leaks can be mitigated as more air is drawn in through the compressor. As a result, the system can still function in a capacity with a small leak. This differs from hydraulic systems where leaks result in continual losses with no fluid replacing what is lost.

- Unlike hydraulic fluid, air can be compressed and energy can be stored. This is useful when the compressor fails, as it allows enough air pressure stored in the air tank to operate the brake chamber, even though no more air is being drawn in and compressed.

- Air brakes can continue to work effectively even with significant leakage in the brake lines. Air brakes are also typically designed with a mechanical fail-safe that stops the vehicle safely using the parking brake in the event of failure.

- Compressed air can also be utilized for accessories, such as air horns and seat adjusters. In a pinch, the engine mounted compressor can also be used to add additional PSI to a low tire, though doing so can damage your compressor.

- Air hose couplings are easier to install and maintain when compared to hydraulic lines. You also don’t need to “bleed” air brakes as part of maintenance.

- Easier to couple to and uncouple from trailers. Air brakes are especially practical when in applications where trailers and constantly attached and removed.

Though there are many benefits to air brake systems, there are also some negatives as well. Air brake systems are expensive and more time-consuming to maintenance, especially within the first 5 years of use. Water, and consequently, ice, can also cause issues in air brake systems. If the air dryers and filters within the system designed to prevent moisture from entering the lines fail, then moisture or ice may enter the lines and rust or even clog the lines.

Air Brake Parts at Iron Wing

There are also wear parts such as brake shoes, pads, and drums that will wear out with continued use. At Iron Wing, we carry a variety of genuine OEM parts, including New Old Stock (NOS) and other hard to find parts. We have parts from MGM Brakes, Bendix, Carlisle, and other manufacturers in-stock and ready to ship now. Browse our inventory of heavy-duty truck brake parts or use the search function to search using part #, description, or manufacturer. Contact us with any parts inquiries via email at: sales@ironwingsales.com