Overview and Applications

Hydraulic motors are used to convert fluid energy into mechanical energy. Compare this to hydraulic pumps, which convert mechanical energy into fluid energy. Hydraulic motors operate as part of a larger hydraulic system, typically at the end of the circuit, with hydraulic pumps at the beginning. Common applications include:

Construction Equipment: Hydraulic motors power excavators, loaders, cranes, and more.

Agriculture: Hydraulic motors are used in irrigation systems, harvesters, and grain augers.

Material Handling: Forklifts, conveyors, and warehouse equipment rely on hydraulic motors for efficient movement and lifting.

Automotive and Transportation: Hydraulic motors play a role in power steering, braking systems, and convertible tops.

And many more applications. Hydraulic motors come in a range of sizes and designs with different tolerances for speed, temperature, and viscosity. In this blog post, we’ll discuss the most common types of hydraulic motors, specifically gear motors, vane motors, and piston motors. By understanding these hydraulic motors, you’ll be better equipped to choose the right one for your specific needs.

Gear Motors

Gear motors use gears (mounted either externally or internally) to convert hydraulic energy into motion. The two gears that make up the motor are the idler gear and the driven gear. The output shaft attaches to the driven gear using a key. Pressurized fluid flows between the gear tips and the housing to the output port, while the meshing of the gears restricting the flow of fluid back to the inlet port.

The advantages of gear motors include simplicity, contamination tolerance, and affordability. Gear motors can have a range of tolerance for speed, temperature, and viscosity depending on their design. Some common uses for gear motors are mobile hydraulics, fans, screw conveyors, driving belts, and dispersion plates.

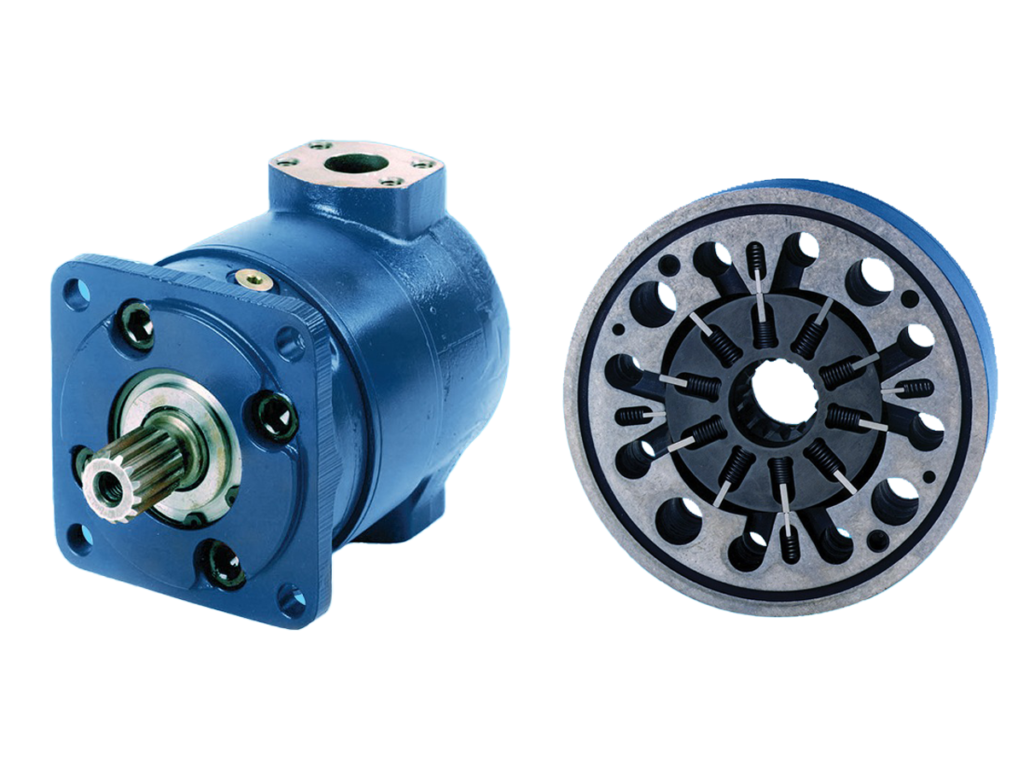

Vane Motors

Vane motors offer a wide range of speeds and can be either Low Speed High Torque (LSHT) or High Speed Low Torque (HSLT). They offer medium pressure ratings and high flows, low flow pulsation, and can be vertically installed. However, they can be sensitive to contamination and need regular maintenance for reliable operation, and speed and torque are only adjustable using a separately attached transmission.

Vane motors are used in industrial machinery, injection molding, mobile hydraulics, and agricultural equipment.

Piston Motors

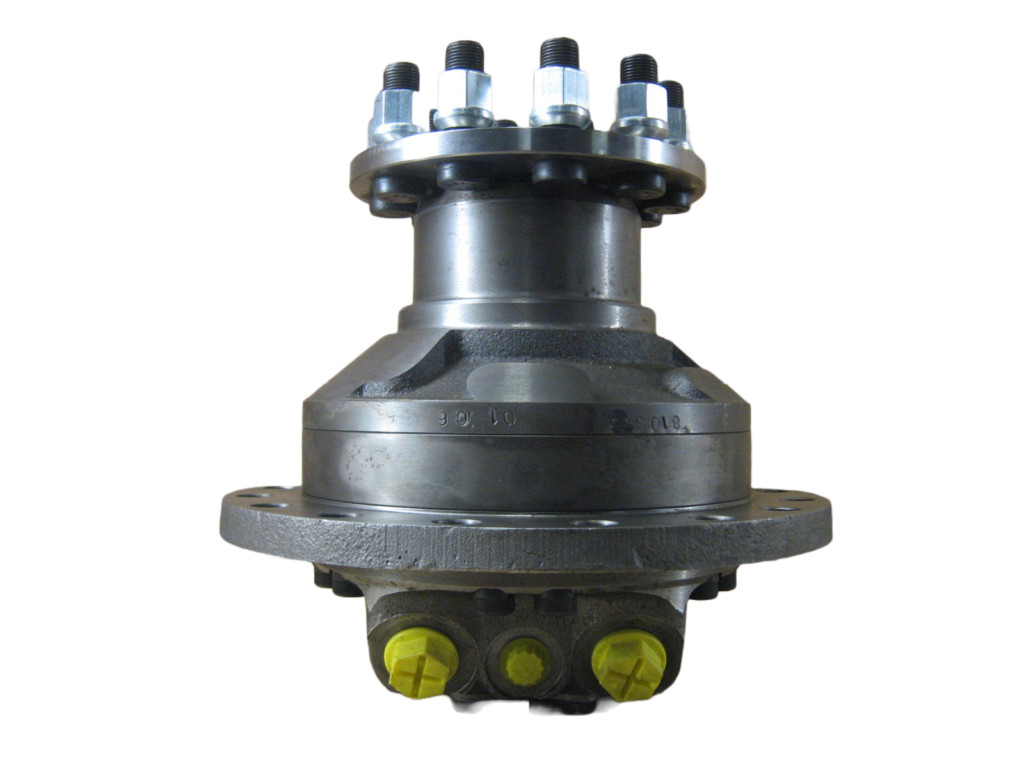

There are two types of hydraulic piston motors: radial and axial.

Radial piston motors consist of pistons arranged perpendicularly to the axis of the crankshaft. As the crankshaft rotates, the pistons are moved linearly by the fluid pressure. The pistons ride against a cam which is connected to the output shaft. Radial motors are Low Speed High Torque (LSHT) motors, capable of smooth outputs at extremely low speeds. Applications for radial piston motors include excavators, cranes, winches, and ground drilling equipment.

Axial piston motors consist of pistons arranged in a circular pattern inside a housing — cylinder block, rotor, or barrel). The housing rotates on its axis via a shaft aligned with the pistons. Axial piston motors are High Speed Low Torque (HSLT). Axial piston motors can be either in-line or bent axis.

In-line designs have the pistons and drive shaft in a parallel arrangement, while bent axis designs feature pistons at an angle (up to about 40°) to the main drive shaft. They use pistons driven by hydraulic pressure to push against and rotate the swash plate, which is connected to the output shaft. Bent axis motors can operate at much higher speeds than an in-line motor of the same displacement. Bent axis motors also offer higher stall or breakout torque.

This performance comes at a cost, as bent axis motors are significantly more expensive. Both variations can be either fixed or variable displacement. They are known for their excellent efficiency and precise control. Axial motors are compact and have a wide speed range, suitable for heavy-duty applications like construction equipment and mining machinery.

Piston motors are typically more expensive compared to gear and vane motors.

Hydraulic Motors at Iron Wing

Looking for hydraulic parts? Iron Wing has a large inventory of Hydraulic parts, including pumps, cylinders, motors, seals, and more.

If you work on hydraulic systems, then check out Hosebox products! Hosebox products make hydraulic maintenance simple with fitting and seal kits for Face Seal, ORB, BSPP, and NPT applications. These kits come with tons of helpful fitting information and formulas, all in an extreme duty waterproof and drop tested case!

All of our parts are In-Stock and Ready-to-Ship in order to help minimize downtime. Search our inventory by part #, category, or manufacturer to find the parts you need.